The Core of Digital Twin Technology

At its essence, a digital twin is a virtual model designed to precisely reflect a physical object. It’s a dynamic, continuously updated digital counterpart that allows for real-time monitoring, analysis, and simulation, bridging the gap between the physical and digital realms.

A. What is a Digital Twin?

* Virtual Representation: A digital twin is a comprehensive, living virtual model of a physical entity. This entity could be anything from a single engine part, a complex machine, a manufacturing plant, an entire city, or even a human organ. It’s not just a 3D model; it contains all the operational data, historical performance, and contextual information.

* Real-time Data Sync: The crucial element is the continuous, real-time data flow between the physical asset and its digital twin. Sensors embedded in the physical asset collect data (e.g., temperature, pressure, vibration, performance metrics) and transmit it to the digital twin. This keeps the virtual model perpetually updated and an accurate reflection of the physical state.

* Two-Way Information Flow: While data flows from the physical to the digital twin, future iterations (and some current ones) also allow for information or commands to flow from the digital twin back to the physical asset, enabling remote control, adjustments, or automated interventions based on simulations.

B. Key Enablers of Digital Twin Technology: The existence and effectiveness of digital twins rely heavily on the maturation and convergence of several cutting-edge technologies:

* Internet of Things (IoT): IoT devices (sensors, actuators, smart meters) are the “nervous system” of a digital twin, collecting the real-time data from the physical asset and feeding it to the digital model. Without a robust IoT infrastructure, digital twins cannot exist.

* Artificial Intelligence (AI) and Machine Learning (ML): AI algorithms process the vast amounts of data collected by IoT sensors, identify patterns, predict future behavior, detect anomalies, and inform decision-making within the digital twin. Machine learning models enable the twin to learn and improve its predictive capabilities over time.

* Cloud Computing: The immense computational power and storage required to manage, process, and analyze the voluminous data streams from digital twins are typically provided by scalable cloud infrastructure. Cloud platforms enable global access and collaboration.

* Big Data Analytics: Digital twins generate and consume massive datasets. Big data analytics tools are essential for extracting meaningful insights from this data, identifying trends, and performing complex analyses that inform optimization strategies.

* Augmented Reality (AR) and Virtual Reality (VR): AR and VR provide immersive interfaces for interacting with digital twins. Engineers and operators can visualize the twin in 3D, overlay digital information onto physical assets (AR), or virtually “walk through” a digital factory (VR) to gain deeper understanding and facilitate training or maintenance.

* High-Fidelity Simulation and Modeling: Advanced simulation software and computational fluid dynamics (CFD), finite element analysis (FEA), and other modeling techniques are used to create the initial accurate digital representation and to run “what-if” scenarios.

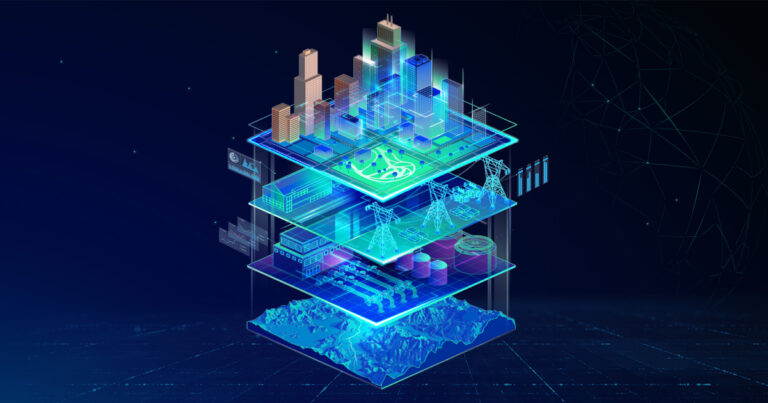

C. Types of Digital Twins: Digital twins can represent various levels of aggregation:

* Component Twin: A digital twin of a single, individual part (e.g., a specific valve in a pump).

* Asset Twin: A digital twin of an entire piece of equipment or machine (e.g., a pump, an engine, a wind turbine). It integrates data from all its component twins.

* System/Unit Twin: A digital twin of an entire system composed of multiple assets working together (e.g., a pumping station, a specific production line in a factory).

* Process Twin: A digital twin that models an entire operational process, integrating data from various assets and systems involved in that process (e.g., an end-to-end manufacturing process, a supply chain).

* Organization/City Twin: A digital twin of an entire organization’s operations, or even a smart city, integrating data from vast networks of sensors, buildings, infrastructure, and citizen activities for urban planning and resource management.

Digital Twins’ Transformative Impact Across Industries

The applications of digital twin technology are diverse and expanding rapidly, offering unprecedented capabilities for optimization, risk reduction, and innovation across a multitude of sectors.

1. Manufacturing

Digital twins are revolutionizing manufacturing processes, from product design to factory operations, enhancing efficiency and reducing downtime.

A. Product Design and Prototyping: Engineers can create a digital twin of a product before it’s even physically built. They can simulate its performance under various conditions, test different materials, and iterate designs virtually, drastically reducing the need for costly physical prototypes and accelerating the design cycle. This enables “first-time-right” product development.

B. Predictive Maintenance: By continuously monitoring the real-time performance data (vibration, temperature, pressure) from machinery, digital twins can accurately predict when a component is likely to fail. This allows maintenance to be scheduled proactively, preventing costly unplanned downtime, extending asset lifespan, and optimizing maintenance resources.

C. Optimized Production Lines: A digital twin of an entire factory or production line can simulate various scenarios, identify bottlenecks, and optimize workflows. Manufacturers can test changes to layout, machine settings, or production schedules virtually before implementing them in the physical world, maximizing throughput and efficiency.

D. Real-time Quality Control: Digital twins can continuously monitor production parameters and product quality in real-time. Any deviation from optimal conditions or potential defects can be immediately identified, allowing for timely adjustments and ensuring consistent product quality, reducing waste and rework.

E. Remote Monitoring and Control: Operators can monitor the status and performance of complex machinery or entire factories remotely through their digital twins. In some advanced setups, they can even remotely adjust settings or troubleshoot issues, increasing operational flexibility and responsiveness.

2. Aerospace and Defense

In highly complex and safety-critical industries like aerospace, digital twins are indispensable for ensuring performance, safety, and longevity of assets.

A. Aircraft Performance Monitoring: A digital twin of an aircraft can monitor every aspect of its flight and ground operations in real-time. This includes engine performance, structural integrity, fuel consumption, and component wear, enabling predictive maintenance and optimizing flight paths for efficiency.

B. Fleet Management and Optimization: Airlines and military forces can create digital twins of their entire fleets. This allows for centralized monitoring of all aircraft, optimizing maintenance schedules, predicting parts requirements, and ensuring maximum operational readiness and safety across the fleet.

C. New Aircraft Design and Certification: Digital twins are used extensively in the design and testing phases of new aircraft. Engineers can simulate aerodynamic performance, structural stress, and system interactions under extreme conditions, accelerating the certification process and ensuring safety before physical prototypes are even built.

D. Life Cycle Management of Complex Systems: From initial design through manufacturing, operation, and eventual decommissioning, a digital twin provides a continuous, comprehensive record of an aircraft or defense system. This helps track modifications, repairs, and performance over its entire lifespan, crucial for complex, long-lived assets.

E. Pilot Training and Simulation: Highly realistic digital twins of aircraft are used in flight simulators, providing pilots with immersive training environments. These twins can accurately replicate real-world conditions, emergency scenarios, and new aircraft behaviors without any risk to physical assets or personnel.

3. Healthcare

Digital twins are emerging as powerful tools in healthcare, promising to revolutionize patient care, medical training, and hospital management.

A. “Human Digital Twins” (Organ/Body Twins): The most revolutionary concept involves creating digital twins of individual human organs (e.g., a digital heart twin) or even entire bodies. These twins, fed with real-time patient data (wearables, medical records, imaging), could predict disease progression, optimize drug dosages, simulate surgical outcomes, and tailor personalized treatment plans.

B. Hospital Operations Optimization: A digital twin of a hospital can simulate patient flow, staff allocation, resource utilization (e.g., beds, operating rooms), and equipment management. This helps administrators optimize efficiency, reduce wait times, manage emergencies, and improve the overall patient experience.

C. Medical Device Performance Monitoring: Digital twins of medical devices (e.g., MRI machines, pacemakers, ventilators) can monitor their real-time performance, predict maintenance needs, and ensure optimal functionality, contributing to patient safety and reliable clinical operations.

D. Drug Development and Testing: Digital twins of human organs or even disease models could be used to virtually test new drug compounds, predict their efficacy and side effects, and optimize dosages, potentially reducing the need for animal testing and accelerating drug discovery.

E. Surgical Planning and Training: Surgeons can use digital twins of a patient’s anatomy to meticulously plan complex surgeries, practice procedures in a virtual environment, and anticipate challenges, leading to greater precision and improved patient outcomes.

4. Smart Cities and Urban Planning

Digital twins are becoming indispensable tools for managing the complexities of urban environments, enhancing sustainability and citizen services.

A. Urban Planning and Development: City planners can create a digital twin of a city or specific urban areas to simulate the impact of new infrastructure projects (buildings, roads, public transport), zoning changes, or environmental policies. This helps optimize resource allocation, predict traffic patterns, and assess environmental impact before construction begins.

B. Infrastructure Management: Digital twins of bridges, tunnels, roads, and utility networks (water, electricity, gas) provide real-time monitoring of their structural integrity, performance, and maintenance needs. This enables predictive maintenance, reduces outages, and enhances public safety.

C. Traffic Management and Optimization: By integrating real-time traffic data, weather conditions, and event information, a digital twin of a city’s transportation network can optimize traffic light timings, reroute vehicles to ease congestion, and provide dynamic public transit information, leading to smoother traffic flow and reduced emissions.

D. Energy and Resource Optimization: Digital twins can monitor and optimize energy consumption across buildings and public infrastructure, manage waste collection routes, and optimize water distribution, contributing to a city’s sustainability goals and reducing operational costs.

E. Emergency Response Simulation: City digital twins can simulate disaster scenarios (e.g., floods, fires, earthquakes) to test emergency response plans, optimize evacuation routes, and assess resource needs, improving urban resilience and disaster preparedness.

5. Energy and Utilities

Digital twins are transforming the energy sector, from power generation to distribution, ensuring reliability, optimizing efficiency, and facilitating the transition to renewable energy.

A. Wind Turbine and Solar Farm Optimization: Digital twins of individual wind turbines or solar panels, and indeed entire farms, can monitor real-time performance, predict maintenance needs, and optimize energy capture based on weather conditions, leading to maximum energy generation and reduced operational costs.

B. Grid Management and Stability: A digital twin of the entire power grid can simulate demand fluctuations, renewable energy intermittency, and equipment failures. This allows grid operators to optimize power distribution, prevent blackouts, and integrate more renewable energy sources seamlessly, enhancing grid stability and reliability.

C. Oil and Gas Asset Optimization: Digital twins of offshore platforms, pipelines, and refineries monitor real-time sensor data to optimize operational efficiency, predict equipment failures, ensure safety protocols, and manage complex production processes, reducing risks and maximizing output.

D. Smart Water Networks: Digital twins of water distribution networks can monitor pipe integrity, detect leaks, optimize water pressure, and manage water quality in real-time, reducing water loss, improving service delivery, and enabling proactive maintenance.

E. Nuclear Power Plant Safety: Digital twins provide highly detailed, real-time models of nuclear reactors and associated systems, allowing operators to monitor every parameter, simulate potential incidents, and conduct training in a safe virtual environment, significantly enhancing safety and operational precision.

Challenges and Ethical Considerations of Digital Twins

While the advantages of digital twin technology are immense, its widespread adoption also introduces a range of significant challenges and ethical considerations that must be proactively addressed:

1. Data Management and Security:

Digital twins are inherently data-intensive, which creates complex challenges.

A. Volume, Velocity, Variety (Big Data): Managing the sheer volume of data, its real-time velocity, and the variety of data types from countless sensors is a monumental task requiring robust data infrastructure.

B. Data Quality and Integrity: The accuracy of a digital twin hinges entirely on the quality and integrity of the data fed into it. Flawed or incomplete data can lead to inaccurate predictions and poor decisions.

C. Cybersecurity Risks: A digital twin, being a perfect digital replica, becomes a prime target for cyberattacks. If compromised, attackers could gain insights into critical infrastructure, manipulate physical systems, or steal sensitive operational data. Securing the data flow and the twin itself is paramount.

2. Cost and Complexity:

Implementing digital twin technology can be a significant undertaking.

A. High Initial Investment: The cost of sensors, IoT infrastructure, cloud computing resources, AI development, and specialized software can be substantial, making it a barrier for smaller organizations.

B. Integration Challenges: Integrating data from disparate systems, legacy equipment, and various software platforms to create a cohesive digital twin is often complex and time-consuming.

C. Talent Gap: There’s a shortage of professionals with the interdisciplinary skills required to design, implement, and manage digital twins, encompassing expertise in IoT, AI, data science, and domain-specific engineering.

3. Trust and Accountability:

As digital twins become more autonomous and influential in decision-making, questions of trust and accountability arise.

A. Trust in AI Predictions: Relying on AI-driven predictions from digital twins requires a high degree of trust in the underlying algorithms. What happens when a prediction is wrong and leads to negative consequences?

B. Accountability for Autonomous Decisions: If a digital twin is used to automate decisions that impact physical assets or human lives (e.g., in smart cities or autonomous vehicles), who is accountable if something goes wrong? The software vendor, the operator, or the AI itself?

C. “Black Box” Problem: Many advanced AI models within digital twins can be opaque, making it difficult to understand why a particular prediction or recommendation was made, hindering debugging and auditability.

4. Privacy and Ethical Concerns:

Digital twins, especially “human digital twins” or city twins, raise significant ethical dilemmas.

A. Individual Privacy: A digital twin of a human could collect incredibly intimate health and behavioral data, raising profound privacy concerns about surveillance, data misuse, and potential discrimination (e.g., in insurance or employment).

B. Societal Control: A comprehensive digital twin of a city could enable unprecedented levels of surveillance and control over citizens’ lives, leading to concerns about civil liberties and authoritarian applications.

C. Job Displacement: While digital twins optimize systems, they can also lead to increased automation and efficiency, potentially impacting job roles that involve monitoring or routine maintenance, necessitating workforce reskilling.

5. Regulatory and Standardization Challenges:

The rapid evolution of digital twin technology outpaces existing regulatory frameworks.

A. Lack of Harmonized Standards: The absence of universally accepted standards for digital twin interoperability, data formats, and security can hinder widespread adoption and create silos.

B. Legal Frameworks: Existing laws may not adequately address the unique liabilities, intellectual property rights, and ethical implications associated with digital twins, especially when physical and digital realms merge.

C. Validation and Verification: How do we formally validate that a digital twin is an accurate and reliable representation of its physical counterpart, especially in safety-critical applications?

Conclusion

The digital twin revolution is a defining technological shift of our era, fundamentally transforming how we design, operate, and optimize complex systems across every industry. No longer a niche concept, these dynamic, real-time virtual replicas are becoming indispensable tools for enhancing efficiency, ensuring safety, and unlocking unprecedented levels of predictive power. From the meticulous precision of manufacturing and aerospace to the critical operations of healthcare and the intricate planning of smart cities, digital twins are the invisible architects of a more intelligent and resilient future.

However, the path forward is not without its complexities. The colossal demands of data management, the imperative for robust cybersecurity, the substantial costs of implementation, and the profound ethical considerations surrounding privacy and accountability require careful and collaborative navigation. Addressing these challenges is crucial to realize the full potential of this transformative technology.

The future trajectory of digital twins points towards highly autonomous, interconnected, and even self-optimizing systems. As they converge with cutting-edge fields like AI, quantum computing, and advanced human-computer interfaces, digital twins will become even more pervasive and powerful, extending their influence into new and unforeseen domains. By proactively investing in the necessary infrastructure, fostering the required talent, and establishing clear ethical and regulatory frameworks, we can ensure that digital twins continue to optimize our systems, not just for economic gain, but for a safer, more sustainable, and more prosperous world for all. The era of the digital twin is here, and it’s set to redefine our reality.